Faux Leather Redefined

At Richloom, we believe that not all faux leathers are created equal. Discover the difference with our exclusive, tiered Tough faux leather collection.

As industry leaders, we make sure that all our Tough faux leathers offer exceptional quality and performance, ensuring long-lasting beauty while meeting the requirements of our customers. For peace of mind, each one of our patterns is also backed by a limited warranty against hydrolysis.

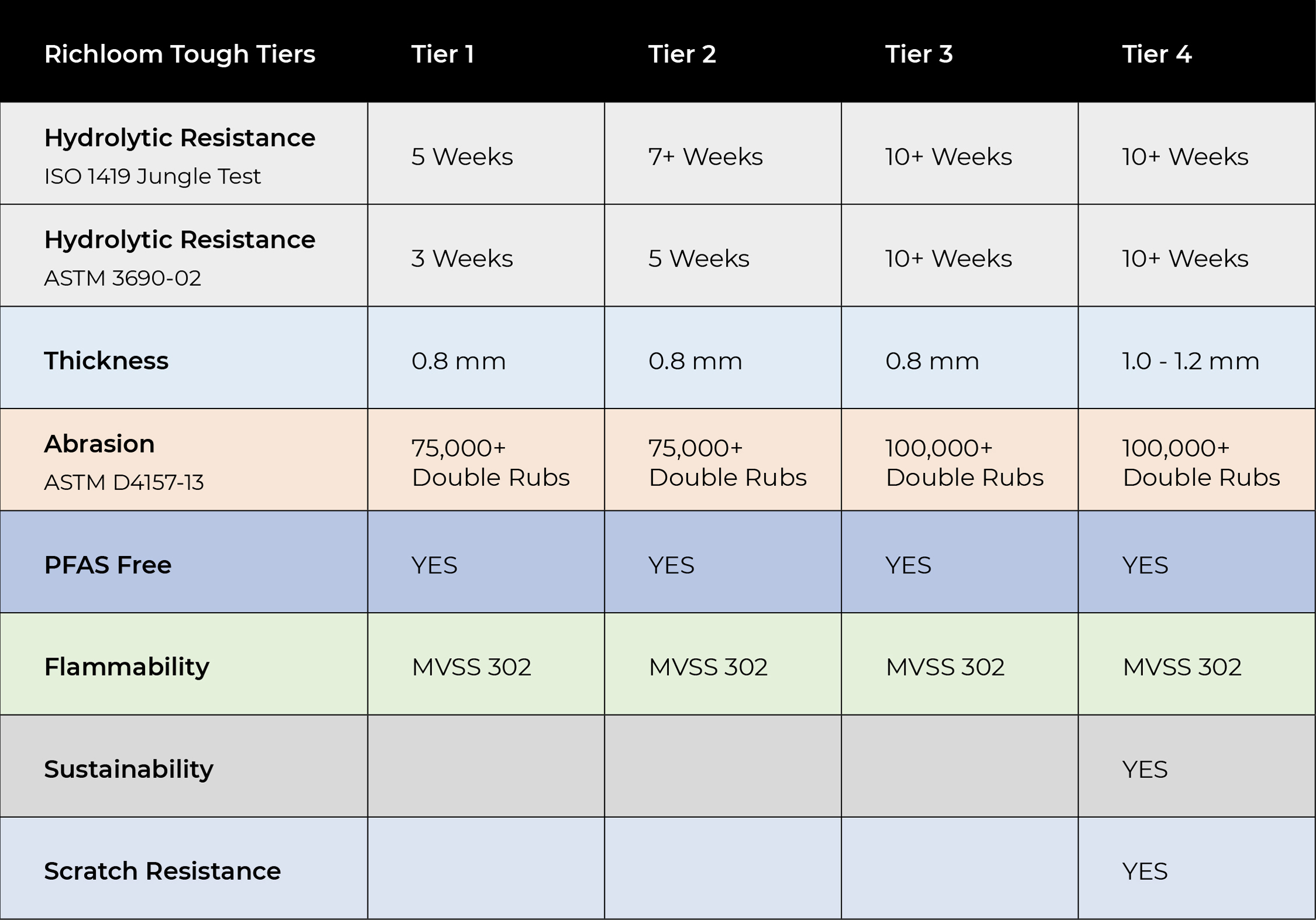

Categorized into one of our four exclusive tiers, every style is meticulously assessed to meet strict industry standards. All our faux leathers undergo rigorous double testing for hydrolytic resistance (ISO 1419 and ASTM 3690), abrasion durability and a series of other tests for mechanical and chemical properties. All Tough patterns pass flammability requirements and are PFAS free.

For our customers requiring the highest level of quality, our Tier 4 patterns offer exceptional durability, are environmentally responsible and scratch resistant.

For more information, please refer to the chart below.

Click here to view the warranty

Click here to view the warrantyHydrolytic Resistance

Richloom utilizes both the ISO 1419 test as well as the ASTM D3690-02 test to determine hydrolytic resistance. Both tests are conducted by placing the polyurethane material in a heat and humidity chamber at 158 degrees Fahrenheit and 95% relative humidity for a period of time. While the ISO 1419 is most well-known in the industry and often referred to as the “Jungle Test”, the ASTM D3690-02 test is the more stringent and comprehensive of the two.

In the "Jungle Test”, the PU material is put into the test chamber and visually examined against a control sample at the end of each one-week period for a pre-determined number of weeks, or until the product breaks down and fails. Failure against the control sample would be in the form of surface cracking, delaminating of the PU film layer from the backing substrate, or extreme changes in color and gloss level. It is generally accepted in the marketplace that a product designed for residential upholstery should withstand at least 3 weeks in the test chamber, and that a product designed for commercial upholstery applications should withstand at least 5 weeks.

All Richloom Tough polyurethanes pass a minimum of 5 weeks, with our higher grades passing 10+ weeks, well above the industry standards.

The ASTM D3690-02 test incorporates physical testing before and after a set period of 15 days in the test chamber. Before the material is put into the test chamber it is tested for adhesion, abrasion and resistance. After 15 days, the material is removed from the test chamber and allowed to recondition at a controlled room temperature for 24 hours, then tested for adhesion, abrasion, and flex resistance. The criteria of all three of these tests must be met for the PU material to get a passing grade. Instead of the standard initial 15 days in the test chamber, Richloom is utilizing the ASTM test at 35 days to ensure that our products meet the most rigorous testing standards used in the contract and hospitality industries.

Abrasion

Abrasion resistance is a material's ability to withstand wear as it faces friction. Richloom utilizes the CFFA1 / ASTM D4157-13 test, also referred to as the Wyzenbeek Method. It is the most recognized test used in the manufacturing of high-quality furniture, office chairs, school and theater seats, and is aligned with testing in the hospitality industry. The test involves rubbing a material back and forth against an abradant, a #10 cotton duck, until it shows signs of wear. The number of rubs required to cause visible wear is used to calculate the abrasion rating.

All Richloom Tough polyurethanes pass a minimum of 75,000 double rubs, while our higher grade polyurethanes rate 100,000 double rubs and beyond.

Sustainability and Scratch Resistance

Richloom is proud to offer some of the most environmentally responsible polyurethanes in the industry. Our Tier 4 polyurethanes are not only extremely durable, but also environmentally friendly.

Due to their inherent chemical properties (Elastomeric Polyurethanes, or the so called EPUs), Richloom’ s Tier 4 polyurethanes offer excellent scratch resistance. They are water based and odorless, with ultra-low VOC rating. They do not include any solvents (0.0 DMFa) or plasticizers, and are free of PVC, formaldehyde, heavy metals, flame retardants, phthalates, BPA, PBDEs (Polybrominated Diphenyl Ethers) and POPs (Persistent Organic Pollutants).

Additional Testing

Richloom’ s entire line of polyurethanes passes the flammability test MVSS 302 and meets or exceeds all testing requirements for tear, tensile and seam strength, as well as color fastness to light. A full statement of test results is available upon request.

In the "Jungle Test”, the PU material is put into the test chamber and visually examined against a control sample at the end of each one-week period for a pre-determined number of weeks, or until the product breaks down and fails. Failure against the control sample would be in the form of surface cracking, delaminating of the PU film layer from the backing substrate, or extreme changes in color and gloss level. It is generally accepted in the marketplace that a product designed for residential upholstery should withstand at least 3 weeks in the test chamber, and that a product designed for commercial upholstery applications should withstand at least 5 weeks.

All Richloom Tough polyurethanes pass a minimum of 5 weeks, with our higher grades passing 10+ weeks, well above the industry standards.

The ASTM D3690-02 test incorporates physical testing before and after a set period of 15 days in the test chamber. Before the material is put into the test chamber it is tested for adhesion, abrasion and resistance. After 15 days, the material is removed from the test chamber and allowed to recondition at a controlled room temperature for 24 hours, then tested for adhesion, abrasion, and flex resistance. The criteria of all three of these tests must be met for the PU material to get a passing grade. Instead of the standard initial 15 days in the test chamber, Richloom is utilizing the ASTM test at 35 days to ensure that our products meet the most rigorous testing standards used in the contract and hospitality industries.

All Richloom Tough polyurethanes pass a minimum of 75,000 double rubs, while our higher grade polyurethanes rate 100,000 double rubs and beyond.

Due to their inherent chemical properties (Elastomeric Polyurethanes, or the so called EPUs), Richloom’ s Tier 4 polyurethanes offer excellent scratch resistance. They are water based and odorless, with ultra-low VOC rating. They do not include any solvents (0.0 DMFa) or plasticizers, and are free of PVC, formaldehyde, heavy metals, flame retardants, phthalates, BPA, PBDEs (Polybrominated Diphenyl Ethers) and POPs (Persistent Organic Pollutants).